Chemical Detection Step by Step

Nowadays, technology is constantly developing in a very rapid rate. This gives different organizations and individual operators a vast variety of possibilities to extend and enhance their actions and procedures in different situations. Manufacturers are constantly looking for new ways to improve the operative capabilities of their equipment and handheld chemical detectors are no exception. Today, almost without an exception, everything is connected. Wireless communications, for example, offer completely new ways of accomplishing missions that essentially leads to increased efficiency and better results. Sometimes it is also good to look back and reflect how things were done back in the day. After all, it is the past that defines the actions in today’s world.

Chemical Detection – Previous Generation

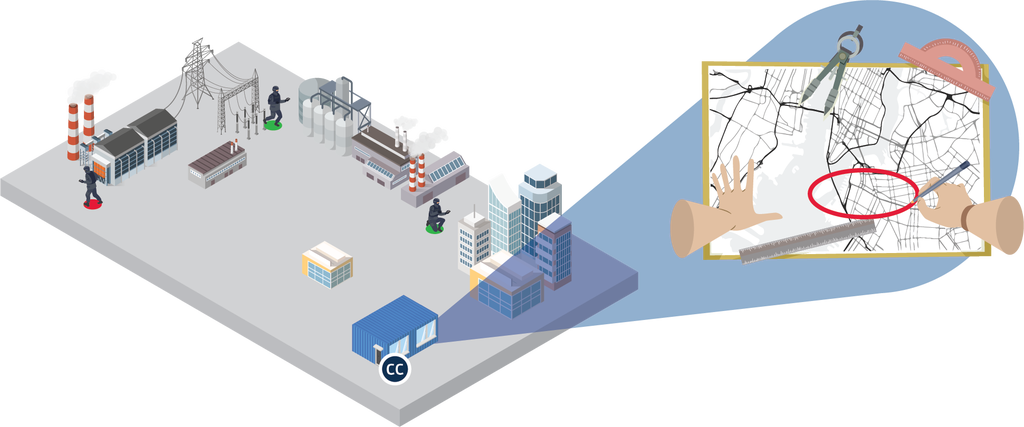

Until now, when talking about handheld chemical detectors, operators in the hot zone used to gather detection results individually and report the results to command and control via communication equipment or after the mission when returning to Command & Control. As sharing the information relied on individual observations and / or external communication equipment, this meant a grown risk for, first of all, the crucial information not being shared with all team members, but also misinterpretation of the observations and detection results. Naturally this also led to information sharing not being very streamlined.

Many handheld chemical detectors offer different operational modes that improve selectivity based on the mission and chemicals of interest. Generally, this means separate operational modes for Chemical Warfare Agent (CWA) and Toxic Industrial Chemical (TIC) detection. However, the problem with this concept is that not always do the operators know, what kind of chemicals could be present in the hot zone. While some manufacturers incorporate a “general” chemical alarm in each operational mode, classifying the target chemical always plays a major role in quick decision making. Also, what makes this concept problematic is that the operator cannot just randomly browse through different operational modes to see, what the classification would be with different modes and expect reliable detection results. Instead, the detector should clear out first in clean environment and operator would have to re-enter the hot zone, again interrupting the streamlined process and efficient decision making.

“Old” traditional method for chemical detection on the field illustration.

Handheld Chemical Detection – The Next Generation

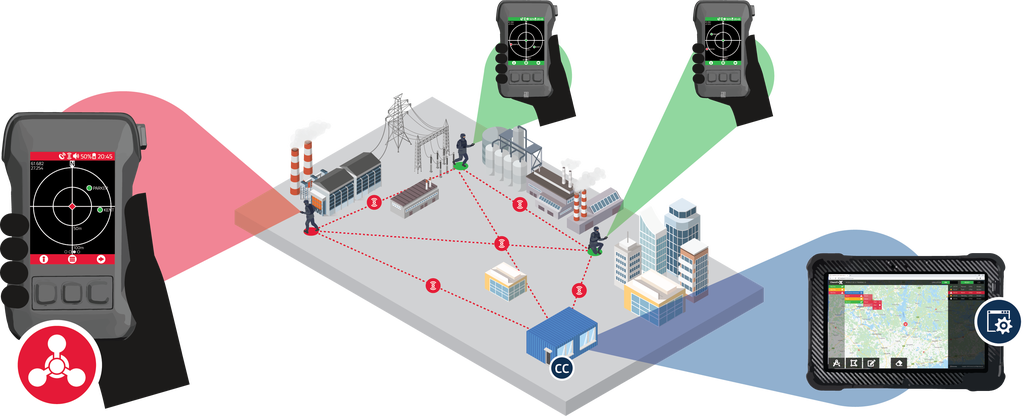

As mentioned earlier, today more and more applications are being connected to each other. It has become a modern standard, that different factors and parameters are monitored “wirelessly”, in real time. The field of handheld chemical detection is also evolving and following these footsteps. Manufacturers are coming up with new innovative ways of revolutionize the chemical detection and operational capabilities. Having the detectors communicate with each other brings huge advantages: no longer do the operators have to collect the detection information individually and share it separately with command and control or other team members. Now each team member can see and observe the status of each individual team member or detector in real-time, constantly: team members can even see, if the chemical concentration on a specific detector starts to rise and therefore focus their efforts on locations necessary even before the actual alarm triggers. Removing the communication “delay” or the risk of misinterpreting the detection results that were present with “previous generation” detectors will greatly streamline the decision making, increase situational awareness and potentially save human lives.

“New” enhanced method for chemical detection on the field illustration.

Some handheld chemical detectors, for instance ChemProX, have also tackled the problematic concept of “restricted” operational modes. Now, all different operational modes for CWAs and TICs run simultaneously all the time when the detector is in operation. This means, that when the detector starts to alarm, operator does not have to leave the hot zone and let the detector clear out in order to see what the alarm indication would be with different operational modes. Now the operator can change operational mode even in a middle of a chemical alarm and be sure that the detection result is still reliable.

Traditional Method vs Enhanced Method Step by Step Comparison Table

| Conventional Handheld Chemical Detectors | ChemProX |

|---|---|

| 1. Operator enters the suspected area of hazardous chemical. Since there is no information what the chemical might be, Operator is using CWA library. | 1. Operator enters the suspected area of hazardous chemical. Since there is no information what the target chemical might be, detection mode ‘CWA’ and ‘Standard’ sensitivity level is selected for use. |

| 2. Detector alarms that something hazardous is in the air. Operator now wants to see, what the alarm indication would be with TIC library. | 2. ChemProX alarms and indicates “Chemical detected”. Operator now wants to see, what the alarm indication would be with TIC detection mode |

| 3. Operator has to leave the hot zone and let the chemical detector stabilize in clean environment in order to ensure reliable detection results. | 3. Since all detection modes work simultaneously on ChemProX, operator does not have to leave hot zone and wait for detector to stabilize. Operator can simply change the Detection mode to “TIC” with lowest sensitivity level “detection”. Alarm indication changes immediately to “Toxic”. Operator can also change the sensitivity level of ‘TIC’ detection mode to ‘classification’ in order to further classify the detected chemical, again, without leaving the hot zone. Alarm indication changes immediately to “TIC Hydride”. Operator is now able to conduct further actions thanks to the classification of the detected chemical |

| 4. Once the chemical detector has stabilized, operator changes the library in use to TIC library. | |

| 5. Operator re-enters the hot zone and detector alarms “TIC”. Operator is now able to conduct more specific actions thanks to the classification of the detected chemical. |

Leave a Reply